24/7 Support: 021 35 623000 marketing@adfengg.com

ISO 9001 : 2015 Certified

24/7 Support: 021 35 623000 marketing@adfengg.com

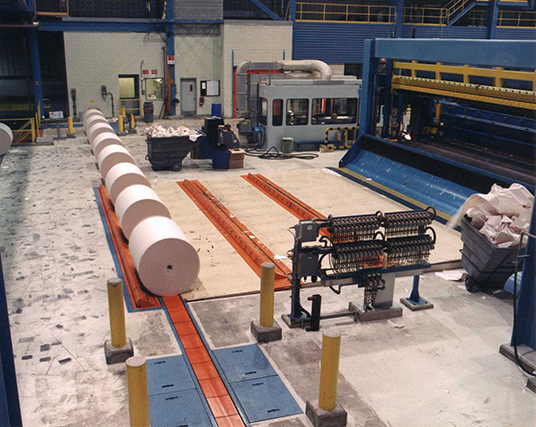

ISO 9001 : 2015 CertifiedAdvanced Dynamics pulper feed systems are an industry staple. The higher the production, the fewer the operators, the BETTER! Our product range covers dried market pulp, wetlap, mechanical pulp, and recycled paper. Wire removal is our specialty. See our latest line of robotic dewirers.

ADF Engineering is your partner in improving your productivity in your paper mill. Our group of highly trained engineers, designers and project managers will help you get the most of your plant on time and within your budget.

We can take on your toughest challenges. Our goal? Increase your productivity. 5 decades of successful business speak for themselves.

We take pride in developing new equipment or an overall material handling solution for your specific pulp and paper mill requirement. Contact us today!

When it comes to kraft pulp bale & wetlap bale handling ADCL is your solution supplier. We know bales; un-wrapper, wrapper, wires on, wires off, plastic straps, re-pulpable straps, glued, single bales, stacked bales, unit stacks. ADCL understands the particular needs for your specific product handling needs to ensure high production throughput, high quality, undamaged superior finished product.

A forefront innovator in recycle bale handling, sorting and dewiring technology. With our continual evolvement of our equipment solution we create better performing equipment the improves our customers’ needs and industry demands. Advanced Dynamics’ R-Dewiring platform covers a wide range of products from:

We can also remove wires or straps from carpet bales to bales of plastic bottles to meet our customers ever changing requirements to recycle.

Market Leadership; ADCL is the number one manufacturer of automatic kraft bale dewiring systems in North America. With 3-generations of proven and field tested automatic dewiring to our “Next Generation”, K2K Robotic Dewiring System. If your product has wires, we can remove them efficiently, and safely. Our solutions can be complete as a system package or can be individual pieces of equipment that can be retro-fitted into your facility.

Copyright © 2018 ADF Engineering Design By Bootestech All Right Reserved.